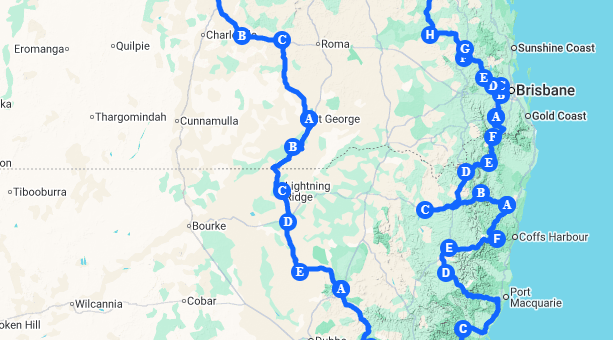

Longreach Trip – National Transport Museum Inverell

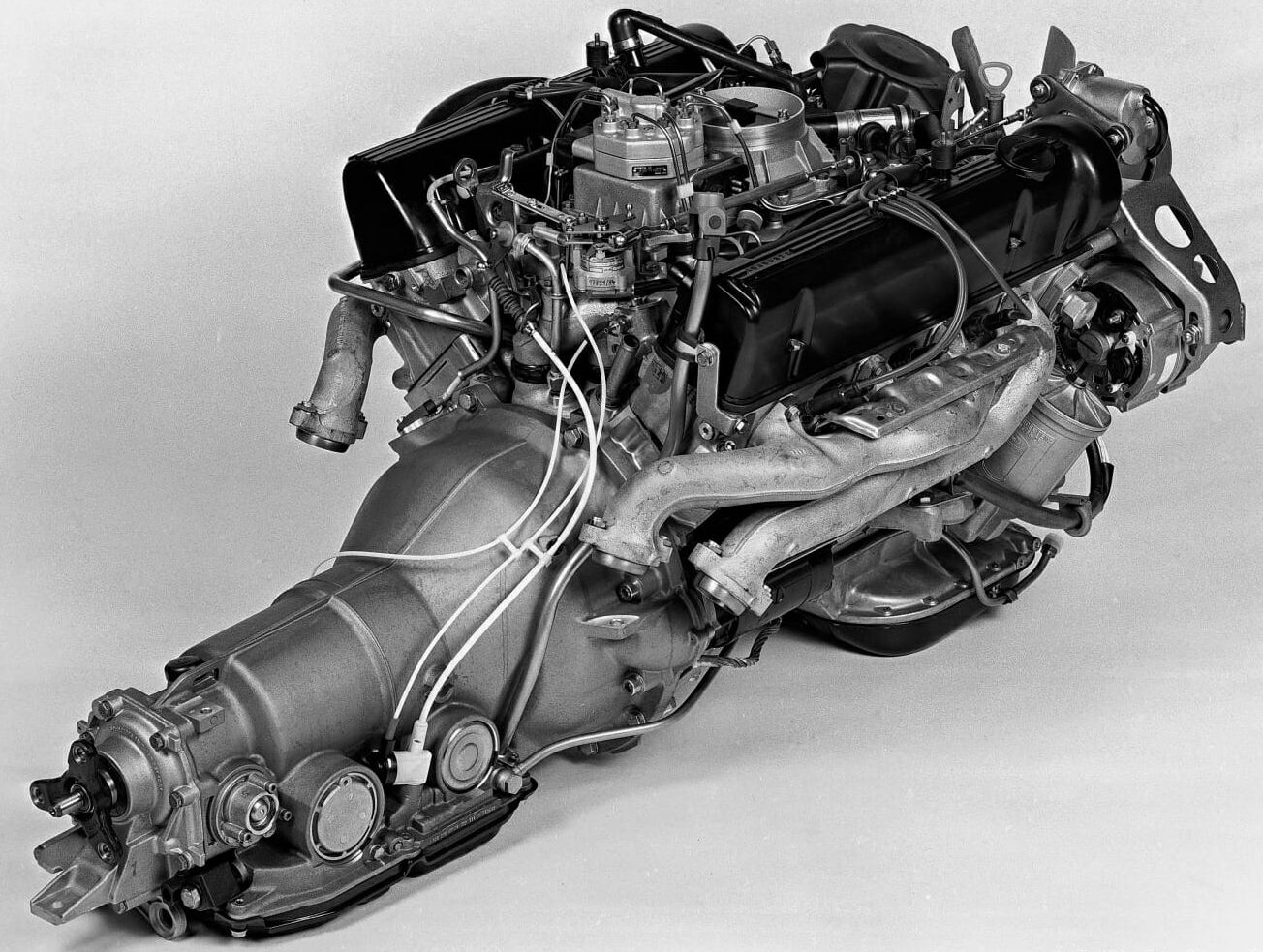

One of the stops on our big road trip to Longreach was the National Transport Museum at Inverell. It was only a minor detour for our group to go and check it out. The museum is in a large shed outside the town. It is quite a big museum, and it is filled with memorabilia as well as the cars. They even had a...