Longreach Trip – Day 5 – Longreach

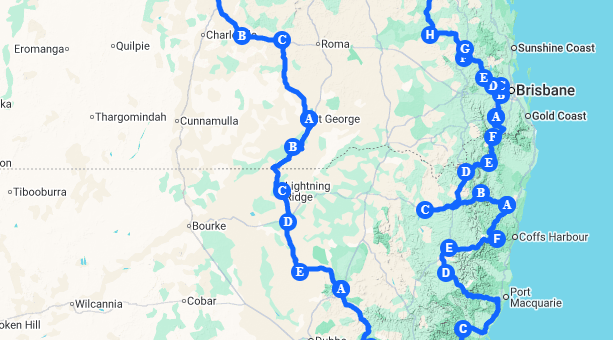

The fifth day of our trip would be the day we finally arrive in Longreach. This trip has been much more about the journey than any one destination, but Longreach is the furthest point from Sydney we will reach. It also marks the transition from our journey there to our journey home. We started out early in Barcaldine. As with our start in Monto,...