| Yesterday I did my first proper drive in my 1981 Mercedes 240D. More information about the car can be found here. My overall impression is that the people who talk about the performance of the 240D automatic on the internet have clearly never driven one. I’m used to driving fairly powerful cars like my 220KW 560SEC but I didn’t find the 240D especially slow around town. I drove around my local area in a mix of heavy traffic, back roads and bigger roads with a speed limit of 90km/h. At no time did I feel like I was holding up traffic or that the car was ‘dangerously slow’ like people claim. During the night drive last night, I was even getting away from the group at times.

In fact, I enjoyed driving the car and would be happy to drive it as a daily. It is certainly more appetizing to me than anything that Mercedes-Benz is making today. You have to adapt to the car and use full throttle a lot more than you would need to in a modern car, but there is something to be said about being able to use all the power a car has. The gearing of the car makes the performance quite good from zero to legal speeds on the motorway. This makes the 240D a good proposition for urban driving and long distance motorway driving. In order to provide good performance, the car needs to be kept in its power band. That means the transmission is kicking down a lot. I could see a situation where the vacuum system had not been maintained and the kickdown switch not working that performance would be poor. In that case the 240D automatic would simply bog down in top gear.

The one type of driving I could see the 240D being unsuitable for is driving on back roads that require overtaking large trucks at 100km/h. Redline in 3rd gear is around 105km/h, so there is no gear to overtake at those speeds. This is where you want a V8 like a 450. In addition, the 240D struggles to maintain speed on long uphill motorway sections. On the most recent night drive, there were a few of those coming home. Speed would drift down to about 85, then I could kick down and bring it back up to about 95. On more gradual grades it would hold a speed of around 100km/h but no more. This is probably where the extra power of the 300D comes in. On a flat section I was able to cruise at 120km/h so the 240D is generally fine on the motorway. Even on the uphill sections where performance is lacking, it is still faster than the trucks. Driving my 240D, I am reminded what a good transmission the 722.1 is when adjusted properly. Nice crisp changes and a hugely rugged unit. I’m not disappointed that my car is a 240D automatic. The automatic transmission is properly set up and works really well. I also found that over the time I was driving the car, it fixed itself. Moving the temperature wheel around had the A/C kicking into life. I guess just a dirty contact in the switch. At first the lighting for the gear selector didn’t work, but that burst into life at some point.

The only thing I took out of the drive to add to my todo list was the thermostat. The car ran a little hotter than I think it should for a day in the mid 20s. There is a lot to like about this car, comfortable, cold A/C, and good on fuel. I drove for nearly 100km before the needle moved off the full position. After I had driven the car around for a while, I went to take a few more nice photos. I was passed by some very expensive luxury SUVs and thought that I would much rather drive my cheap 240D. Today I had to go and pick up some things from the inner west of Sydney. Narrow roads and heavy traffic. The 240D was a great car for this, nimble, comfortable and excellent on fuel. Plus the around town performance really is quite good. I’ve now done 350km and the fuel tank is still showing more than half. Of course, its a Mercedes, so once it gets below the half mark, it will be empty in no time, but it really is very good for a car of this age. People who think these are dangerously slow should actually drive one. I’m really enjoying mine. The April 2024 night drive was a repeat of a route we last did two years ago. On that night, I tried two different cars before withdrawing, both of them having brake issues. In addition, recent bad weather kept the numbers down. This month was a much better experience all around. The drive was dubbed the ‘Bridge to Bridge’ drive. Basically we would take the back roads from Windsor Bridge in the north west to Peats Ferry Bridge in the north, going via Berowra Waters ferry. Since it was a double demerits weekend, the 240D seemed like the perfect car for the drive. It was also a good opportunity to see how it went on twisty roads and a motorway section. Our meeting point was McDonalds in Windsor, where we had six cars on the drive. These were my 240D, a 380SEL and 380SEC, W124 230E, 300TE and a modern C350 diesel.

My 240D was in the lead and was quickly able to show that the 240D is not the slow car people think. Our drive started going up past Scheyville to Cattai ridge road and then taking that towards the Berowra Waters Ferry. From there, we took the Old Pacific Highway to Peats Ferry Bridge, before taking the motorway back to our ending point at a 7/11 in Berowra. As usual for these types of drive, there was very little other traffic on the road. Our group was a good size to catch the Ferry and we were all able to stay together. After the 7/11 stop, it was a 40 minute drive back for me, with a motorway section first.

My 240D did well, and it continues to show what a great car it is to drive. It handled the twisty sections well, and the car had plenty of power for most of the drive. The only section is struggled a bit was the long uphill motorway section going south from Peats Ferry Bridge. Speed would slowly sink down to about 85km/h where I could kick down and then accelerate back up to about 95 before repeating the process. Once the road flattened out, I was able to maintain 110km/h, although there were some slight gradients that pulled speed back. I only noticed two things about the car. The first was that even at night the temperature seemed to high. It would mostly sit around 100C. It generally didn’t get much lower, but occasionally it would go down to about 90C. During the second motorway section it rose to about 110C, and I had to back off and turn on the heater. My theory is that I have a sticky thermostat, as by the time I got home, the temperature seemed in the mid 80s. My first port of call will be to change the thermostat and see if that improves things.

When I parked the car, I also noticed that the oil cooler was cold to the touch. I will keep an eye on this, I would rather not change the oil thermostat as that seems like a major job. Overall, I was very happy with the 240D and I enjoyed taking it on the drive. I probably gave it an ‘Italian tune up’ of sorts. With the 240D now registered and in the garage, there were a few simple jobs to undertake. The first was a set of floor mats. The original carpets were in such nice shape I wanted to protect them. I though the ideal floor mats for the 240D are the dealer fitted thick rubber mats from that era. Its likely what the car had when new. I had one more partial set of those mats in my parts storage – just missing a drivers mat. For the drivers mat I had to substitute a cheap generic mat. If I can’t find another drivers mat, I may move the mats from the 450SLC to the 240D and replace those.  Next was to check tyre pressures including the spare. The spare was quite low, and ancient. At some point I’ll replace the main tyres and put the best one as the spare. Next was to check tyre pressures including the spare. The spare was quite low, and ancient. At some point I’ll replace the main tyres and put the best one as the spare.

After that was the oil change. I spoke to somebody who used to service these cars when new and I was advised not to bother with a specific diesel oil and use the regular Penrite 20W/50. The oil was black, but that seems to be the norm in a diesel. When I removed the filter, everything looked ok.  I would have preferred to drain the oil from underneath using the hoist, so I could inspect the underside of the car. However, my hoist is currently broken so I sued the vacuum pump. The 240D has quite a large oil capacity for a four cylinder engine. I would have preferred to drain the oil from underneath using the hoist, so I could inspect the underside of the car. However, my hoist is currently broken so I sued the vacuum pump. The 240D has quite a large oil capacity for a four cylinder engine.

Since I don’t know when the last oil change was, I’ll probably do another one with a much shorter interval. I also gave the car a wash after its trip on the tow truck. Even the wheel arches are quite clean on this car. When I got the pink slip, the mechanic who did it suggested I change the motor mounts and the transmission shift bushings. I’ve ordered some, and will add that to the to-do list.  The fuel gauge was indicating a little over half a tank. The easiest way to make sure that is working was to fill the tank to the top. This verified that the gauge was now working and I had a full tank of diesel. The fuel gauge was indicating a little over half a tank. The easiest way to make sure that is working was to fill the tank to the top. This verified that the gauge was now working and I had a full tank of diesel.

Looking around the car, I noticed that the first aid kit was missing. Luckily I had one that I was able to add. Not for use, but I like these things to be correct. I was now ready for a longer drive in the car. Sometimes you don’t go looking for classic cars – they find you. While I have always wanted to try a W123 diesel, I wasn’t specifically looking for one. However, when I saw this 1981 Mercedes-Benz 240D, I thought it was something special. I was able to secure it for what I thought was a very good price. The main thing that appealed to me was how original the car looked. So many of these cars had a very hard life and are still running in spite of that. This car looked like it had been used carefully and had been the pride and joy of its owners. I’ve outlined a lot more detail about the W123 240D and this car on this page.

This will be my third W123. My first was the first ever Mercedes-Benz that I ever owned – a 1985 230E. The second was a 280CE that I rescued from sinking into the mud in somebody’s front yard, fixed up and sold to my brother. While the 230E was a very nice car, this 240D is in nicer condition, and I sold the 230E over twenty years ago. My W123 diesel is painted in China Blue, which I think is the nicest of the standard W123 colours. The paint appears very original, as does the dark blue MB-Tex. As you would expect for an Australian delivered 240D, it was bought with no options. Australian delivered 240Ds came standard with air conditioning, power steering, central locking, a Becker Europa 596 & power antenna, a front arm rest and a passengers side mirror. You didn’t even get a lockable glovebox. I like the simplicity of the options, it feels in keeping with the car.

I bought the diesel sight unseen. This is somewhat of a risk, but I work a lot and would not have been able to go and look at it. The price was such that if it had been a lot worse than I thought, I could have just sent it to auction and not been too out of pocket. The car arrived on a tow truck last weekend and I was able to drive it around the industrial complex where I store most of my cars. I was quite impressed. Nearly everything seemed to work, other than the A/C. The car was very much as described. Everyone describes how slow the 240D automatic is, but my first impression wasn’t of a slow car. The tyres are on the older side, but still in very good shape. The engine was very clean and was not leaking oil or diesel.

I didn’t think the car needed anything to get registered, so I booked it in for a pink slip. The car passed inspection, and with pink slip in hand, I was able to get it on club plates. While there car was in having the pink slip, I asked him to see if he could re-gas the A/C. It took a charge, but the compressor was not turning on with the switch, although he was able to get cold air if he applied voltage directly to the compressor clutch. Due to the silly size of the NSW club plates, I had to make up an adaptor. I had a spare blank plate for the rear, but not for the front. In the end I found a previous adaptor I had used on the 250SE. I’ll probably change it for a black one later. On my way back from getting the car registered, I also picked up a few oil filters. I have the original service book, but not recent history so an oil change will be one of my first jobs.

Late last year the power window on my 1987 Mercedes 560SEL stuck in the down position. I lowered the window to exit a parking station and the window would not go back up. The first test I did was to check the switch. This would have been the easiest and simplest repair. It is very easy to swap the plug on the front and rear switches, but unfortunately I was able to rule out the switch. At that point I was preparing the 560SEC for the concours run and the 300TE for the Tasmania trip, so I parked the 560SEL to look at after those events. I assumed that the problem was going to be a broken plastic slide in the window regulator. This is a very common problem on the W126. I was so sure this was the issue that I bought a couple of these slides online.

Earlier this year, I finally removed the door trim and the slide was in perfect condition. Removal of the W126 door trim is wel documented, but there are a few gotchas. The first is that the trim should never be pulled outward until it is pulled up and plastic hooks are clear of the door. They will break otherwise. Secondly, there is a tiny plastic circlip in the electric seat switch. This is often missing, but was still present on my car. All the other doors I’ve removed the trim that had power seats were missing that circlip.

I couldn’t see any obvious issue other than the window being stuck. At this point I was preparing for a couple of work trips, so I took the car to a mechanic to take a look at it. He removed the regulator and diagnosed a bad window motor. He showed me how the plastic gear inside the motor was binding up preventing the motor from working. Enter the 420SEL parts car. I removed the motor from the front drivers side. The other motors are different and have different part numbers. The parts car motor looked a bit manky but it did work. I cleaned it up as best I could and dropped it off.

The parts car motor did the trick and I got the car back with a working window. My job was to put the trim back on. The first part was replacing the moisture barrier. The original one had a few rips in it, so my daughters and I made a new one from some plastic sheet, using the old one as a template.

As well as the moisture barrier, I also replaced the pot metal bracket that goes around the door pull, and exchanged the door pull with one with slightly less play in the mechanism. The door pulls from the rear doors are the same and are generally less floppy. The metal bracket was broken as can be seen.  The main trick with getting the door trim on is to remove the little trim strip that goes alongside the window aperture. It is held in with a single screw and then it lifts upwards and away. This allows the top of the door trim to better fit into the channel near the window. The main trick with getting the door trim on is to remove the little trim strip that goes alongside the window aperture. It is held in with a single screw and then it lifts upwards and away. This allows the top of the door trim to better fit into the channel near the window.

The puddle light is also a bit of a pain as once its connected you need to keep the door trim near the door. From there the job is fiddly but not all that hard. The main thing is not breaking any of the clips when re-attaching the trim.  It’s been good to have the 560SEL back and operational. I’ve been driving it pretty much daily for the last week. It’s been good to have the 560SEL back and operational. I’ve been driving it pretty much daily for the last week.

A few months ago, I started replacing the blower on my W124. I figured this would be a simple job and I would be back up and running a few days later. Little did I know that that the car would be off the road for months. In part one, I removed the old W124 blower motor. I was not able to install my replacement motor, because it did not fit. I figured the issue was with the aftermarket part, so I ordered a brand new genuine W124 blower motor.

This arrived, and it was much better, but still not a perfect fit. It was still scraping on the housing somewhat. I spent a lot of time trying to get it to work without scraping. After trial and error, I found that the original bracket worked better than the one that came with the aftermarket fan, especially after trimming a little material from it. I also used only two of the three screws holding it on, with the rightmost screw very tight and the leftmost screw missing. With a lot of pushing and prodding I was eventually able to make it run with minimal scraping. The right squirrel cage really needed to be about 50mm further to the right. I found the easiest way to do it was to leave the fan running while I did the re-assembly. That way I knew right away of something I did made the fan scrape again. This was particularly important when putting the lid on the housing and re-fitting the mono-wiper. I found sometimes I had to push on the housing again to stop the scraping. I hope that does not mean issues going over every bump or a sharp corner.

Getting the mono-wiper back on was quite fiddly. When I removed it, I had left the wiper blade on. In retrospect this was rather silly and it was much easier with the blade removed. I found it was easiest to position the fan motor first from the bottom, plug in the connector then position the assembly. There are four nuts plus the clip that go on to secure the mono-wiper. Two of the nuts are not easy to see, obscured by the rubber trim around the wiper base. I also used a little grease on the joints of the wiper mechanism, at least those that were visible from the rear of the assembly. Once I had the mono-wiper back on, I realized that the flap at the top of the blower motor was down. I was pretty sure this was up when I first started this install. Sure enough, it was. This didn’t seem to be right, so I removed the mono-wiper and the top of the housing.

It turns out there is a linkage between the flap and a pivot point behind it. I’m not sure if the linkage was broken, or had just come off, but I could not get it back on. At this point I really wanted to get the car back on the road, so I left the flap in the halfway position and re-installed the W124 blower motor cover and the mono-wiper. I had just wasted two hours. Getting the rest of the trim back in wasn’t too bad. The trim on my car is not in the best of shape in a few places, especially the lining of the inner firewall. I would love to get some better parts from a wreck at some point. Having the 420SEL parts car was quite a big help here. I was able to replace a few nuts and screws that were missing (or I dropped).

I was also able to clean out some water drains that were totally blocked up. In one area, I didn’t realize there was supposed to be a drain it was so blocked up. I didn’t have time to take the car for a test drive, but everything is now back in and ready to go except for the wiper blade. I’m glad this job is finally done, and I can use the 300TE again.

I’m back in the USA for an annual conference I attend. I normally have a free day before it starts, to get acclimatized to the time zone and to allow a buffer for flight delays. The conference is in Las Vegas, which has become really expensive. I’m not all that interested in spending money on overpriced entertainment, or gambling when I could spend money on needy old cars. Thus, I headed back out to the self service junkyard.

This year I didn’t think I would end up going. A few days before my trip, I checked the inventory at both Junkyards I use in Vegas. The oldest car was a 1992 190E. My luck changed though, and a 1991 300E and a 1986 560SEL were both added to the list. That meant not only were there two good models for me, but both would be not too picked over. I did my usual thing and bought some tools and took an uber out to the location. On the way to the Mercedes, I passed a Alfa Romeo Spider and a Jaguar XJS V12. Not normally cars one sees in the self service junkyard.

In the Mercedes-Benz section the most common car was the W220 this time. However, the W126 and W124 were next to each other. The W126 was in much better shape than the W124. While the paint was faded, the interior was actually quite nice still. Somewhat sun damaged, but still quite nice. The 300E looked like it had been neglected for 20 years.

The 560SEL was a very early one. I looked up the data card (WDB1260391A19661) and it was produced 9/85. Series 2 started in August with #186069. This 560SEL had engine number #000196, showing how early it was. I had read the change to Series 2 did not all happen at once, and this car confirmed that. While it was basically a series 2 car, it had a series 1 rear parcel shelf. It also had the fanfare horn button on the console as do 1986 models. The car was in a striking combination of Anthracite (172U) with Anthracite leather (271). This combination would have never been ordered by an Australian dealer unless the customer insisted.

My criteria for getting parts is that they need to be easy for me to carry and put in my luggage. Therefore, an original alloy wheel in the spare wheel area of the 560SEL was not on the cards. The most obvious and easily flipped parts were already gone, sine the car had been there a week. Still, there was quite a lot I could get. Probably nothing especially exciting, but for the cost all good spares to have on hand. Some of it was similar to what I was able to get last year. Since I just used up my spare drivers side window motor on my 560SEL, I grabbed the passengers side unit from the parts car here. I also got lots of useful switches and relays that are great to have on hand. While I now have other SLS spares, it can never hurt to have more at these prices. So I set about removing the SLS. Since I had to remove the rear seat, I grabbed the seat motor too.

The SLS proved more difficult than anticipated, I was able to return early the next morning with a 17mm ring spanner and finalize the removal before I had to start work. I’m getting quite fast at stripping SLS struts from wrecks. I also took the chrome strip for the boot of the 560 as mine is a bit discoloured, This one is not perfect but it looks a little better.

On the W124, I took the comfort control module from under the seat and a few small misc items, such as a couple screws that are missing on my car for the mono wiper. I didn’t bother getting any switches as they were so badly sun damaged. The Hirschmann antenna came from the W124 too.  if I go again next year, I hope they have more W124s. Its too much to hope that there will be older cars, but while I now have a good supply of W126 parts, I would like to build up my stock of W124 parts. The picture above shows some of the parts. The SLS parts are very greasy, so in the plastic bags. if I go again next year, I hope they have more W124s. Its too much to hope that there will be older cars, but while I now have a good supply of W126 parts, I would like to build up my stock of W124 parts. The picture above shows some of the parts. The SLS parts are very greasy, so in the plastic bags.

I just got my 450SLC back from having the timing chain, tensioner, camshaft oiler tubes and valve stem seals replaced. These are all jobs that any owner of a Mercedes V8 of this era will need to undertake at some point. The primary driver behind this was the need to replace the valve stem seals. A couple of my sparkplugs, #1 in particular, would regularly foul up. I didn’t have a lot of visible smoke, but I did see the odd puff of smoke taking off after a period idling. This is a pretty common problem in these engines. Age, and lack of use cause the valve stem seals to harden and allows oil to get into the cylinders, in particular at idle. A number of these engines have been prematurely rebuilt due to this simple issue. It also seemed sensible to change the timing chain at the same time. I understood that it had been done a year or so before I bought the car in 2003. I didn’t have any evidence for this. Removing the valve covers showed that the chain had been replaced at some point, as had the guides. However, I wasn’t sure the age of the chain and the guides were now coffee coloured. I started by ordering the parts I would need. The part numbers I ordered are listed below. I don’t guarantee these are correct for any other car. For a lot of these parts I prefer genuine given their importance to the engine and how expensive this job is.

- Timing chain – 000 997 76 94 – IWIS (In a Febi Box)

- Timing chain tensioner – 117 050 10 11 – Genuine. This is the tensioner with the port for air injection. It is quite expensive. The air injection system on my car has been disabled and it was not clear to me if I could have simply used the normal tensioner.

- Camshaft oiler tube kits x2 – 117 180 00 84 – I wanted genuine, but they are now NLA so purchased Febi.

- Chain guide x2 – 117 052 09 16 – Genuine

- Chain guide x2 – 117 052 08 16 – Genuine

- Tensioner guide – 117 050 04 15 – Genuine

- Guide pin – 116 052 21 74 – got a couple in case they were needed, but they can normally be reused.

- Left valve cover gasket – 116 016 13 21 – Elring

- Right valve cover gasket – 116 016 14 21 – Elring

- Valve cover copper sealing ring x8 – 915035 000016 – Reinz

- Valve stem seal kits x2 – 116 050 01 67 – Genuine

While I was there I also ordered some other parts I needed that will be used later, such as the drier pictured above. I also grabbed the two pictured air hoses to be replaced at the same time as they were rock hard. There were no major issues during the job, although my mechanic noted that the valve stem seals are much harder to do in the 107 than the 126. There is far less room, particularly up near the brake booster. The oil seals immediately showed why I had an issue with oil getting into the cylinders A couple had cracked and the rest were so hard they were not sealing properly.

It would appear that Mercedes-Benz revised these seals at some point. The new ones were rubber, whereas the old ones were a hard plastic type material. During the timing chain job, a couple of the lifters need replacement. Unlike during the timing chain job on my 560SEC, none of the guides were broken, but they were all discoloured. It is not clear how many kilometres were on my chain, but the camshaft sprockets had a reasonable amount of wear on them.  After the job, my mechanic performed a compression test on my engine and he was very happy with the results, even after 313,000km. The car runs very well now, and seems to even have a little more power. This was quite an expensive job, but necessary if you are going to own a Mercedes-Benz v8 of this era. After the job, my mechanic performed a compression test on my engine and he was very happy with the results, even after 313,000km. The car runs very well now, and seems to even have a little more power. This was quite an expensive job, but necessary if you are going to own a Mercedes-Benz v8 of this era.

In addition, during the timing chain job, I had the tensioner, guides, and camshaft oiler fittings replaced as per the parts list above. These should always be done at the same time. I’ve wanted to visit the Fox Collection in Melbourne for over 10 years. I used to have a job where I would commute to Melbourne twice a month but the opening hours never lined up with when I was there. This weekend I am traveling through Melbourne and happened to have the Saturday morning fee. I went along for the morning with my kids. The Fox Collection is a part of the personal collection of Lindsay Fox, an Australian trucking magnate. Lindsay Fox is now 87, and has been collecting these cars for years. As well as the public part of the collection, there are apparently another 300 or so cars out near Essendon Airport. The collection is housed in a heritage warehouse in the Melbourne Docklands area. This makes it very easy to get to. There is also plenty of parking if you are a local. The collection is housed over two floors. On the ground floor, there is a general room with high end cars on one side, and performance cars on the other. There are also a couple of trucks from the early years of Mr Fox’s trucking empire.

Additionally on the ground floor is the Ferrari Room. Upstairs there is a Mercedes-Benz room and a Porsche Room. Nearly all the cars are pretty special. In the general room you have cars like a Mercedes-Benz 540K Roadster (my favourite) along with an Derby Bentley and an Austin Healy 100S. The room also contains the only remaining Rolls Royce Camarge prototype. The Ferrari room contained an F40, F50, Enzo, 288GTO and a 246Dino. From this room I would take the 288GTO. Its not the most valuable, but the one I would like to drive. That assumes I would fit in. Upstairs the Porsche room has a collection of rare 356s as well as some other interesting cars from Porsche’s heritage and a few modern sports cars. In the Mercedes Benz room there is a Gullwing, a Pagoda, 190SL plus some very rare performance cars like a McLaren Mercedes, SL73, SLR and others. There is also one of only two AMG A38 cars, a twin engine version of the little city car. I would take the Gullwing. I enjoyed the Museum. About an hour is all you really need. The museum focuses on quality rather than quantity. Still, given there are around 300 extra cars, I think the could easily fit another 10-20 cars in the space at the docklands which would be a useful improvement to the museum. Regardless I would recommend the museum if you have an hour or so free in Melbourne on a Saturday morning or Thursday. One of my favourite day trip drive near Sydney is the Oberon to Goulburn Drive. I’ve done this drive in both directions and its a great mix of different roads, plus limited traffic. I even incorporated this road in my recent trip to Melborne. I had also seen that the parallel road that goes south out of Bathurst was also paved in the last 10 years. This road head south until it hits Crookwell, where you can either keep going south to Gunning, or veer off to Goulburn.

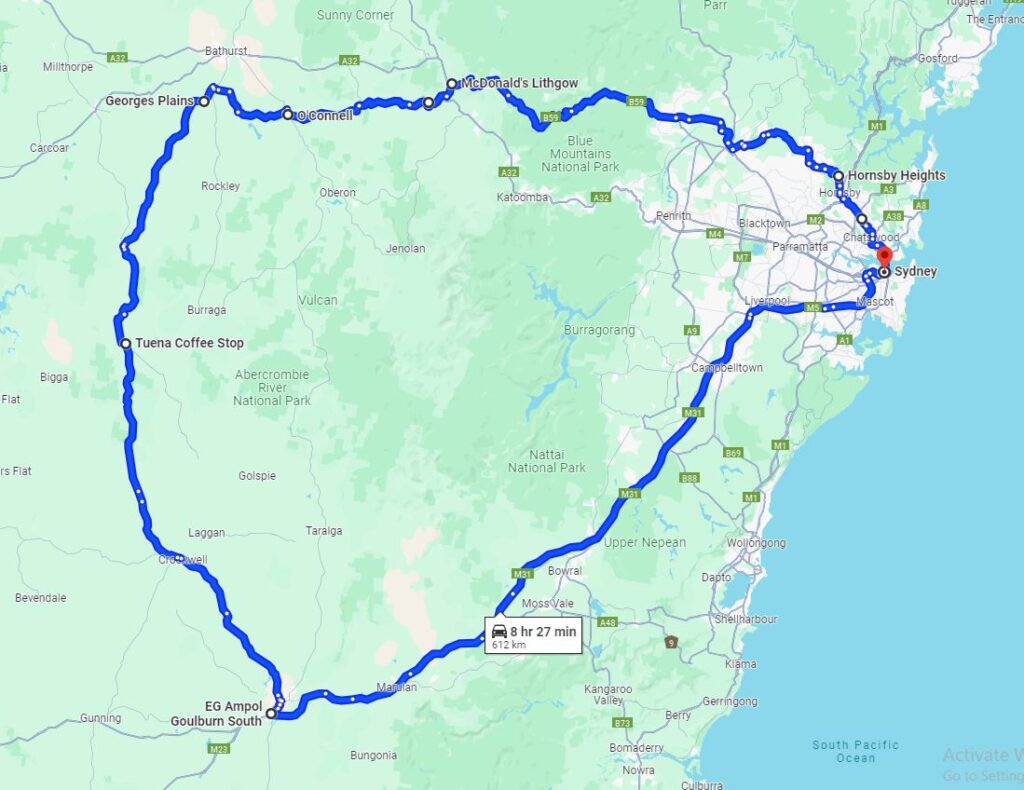

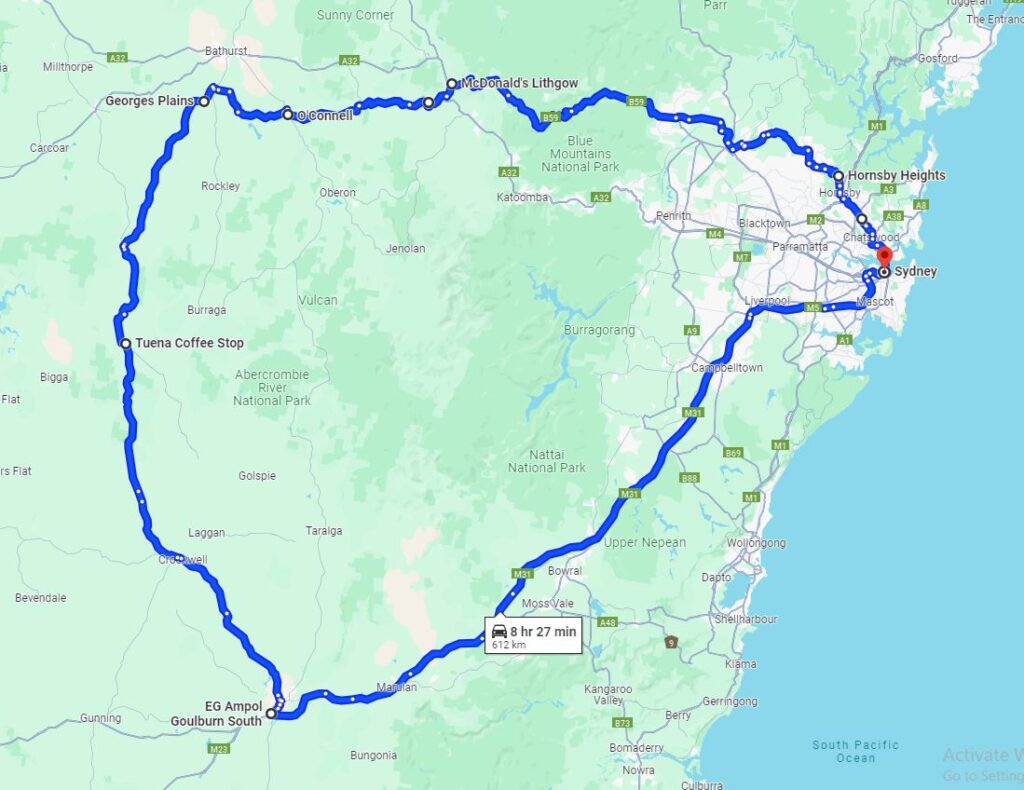

I wanted to try this as another full day trip from Sydney, as well as have it as a candidate as part of bigger road trips. I had a full day free, so I got a small group of friends together and we went and tried it out. We met at McDonalds Lithgow. I took the back way there, via Galston Gorge, Maraylya and Bells Line of Road. This is a pretty good drive in itself and far better than the obnoxious Great Western Highway. We had three cars on our drive, my 560SEC a 380SEC and a W211.

From Lithgow, we left the main roads and headed towards Lake Lyell. This was quite a scenic spot and we continued past it towards O’Connell. Parts of this road were good and other parts were full of large potholes. We past the turn offs to Oberon which would have taken us on the normal road to Goulburn. We continued along towards George’s plain before heading south towards Tuena. The main part of the road south was pretty good. There was minimal traffic and it was quite scenic. We stopped for Lunch at the little coffee shop at Tuna before heading south towards Crookwell and Goulburn. We all really enjoyed the drive. If I had to pick, I would probably rate the Oberon – Goulburn road slightly better. However, the combination of both allows for an interesting possibility of doing a more adventurous day trip of avoiding the M31 and doing both roads in a single day. It would add another 100km and a few hours to the trip, but I think be worth it with an early start. I was pretty happy with my SEC performed on the trip. The owner of the 380SEC had just replaced his valve seals and that car was running better than ever. The W211 also made the trip without incident. It is probably one of the nicest series 1 W211s left in the country. | |